In recent years, the world has experienced a clear warming trend, with longer and hotter summers. For professionals in agriculture, greenhouse construction, and outdoor shading, this shift has become a defining factor affecting productivity, energy costs, and comfort. According to USDA reports and recent research, extreme heat has cut global vegetable yields by up to 20 %, raised fruit tree sunburn rates by up to 40 % in key growing regions, and increased demand for shade structures (both on farms and in cities) by 30–50 %.

Against this backdrop, shade cloth (also known as shade net) has evolved from a simple sun barrier into one of the most practical, cost-effective, and sustainable passive cooling solutions available today. As a global shade cloth manufacturer with over 20 years of experience, INSONSHADE has compiled this guide to help you understand the 12 different types of shade cloth, their features, and applications.

Quick Reference: Shade Cloth Types and Applications (2025 Edition)

The market today offers dozens of shade fabrics that vary by material, color, weave structure, shading percentage, and application. In theory, shade cloth can be classified from multiple perspectives — by fabric type, shade rate, color spectrum, or even intended use, such as agriculture, construction, or landscaping.

Don’t Miss: What color shade cloth is best for tomatoes?

However, in real-world use, only about a dozen types of shade cloth have demonstrated consistent long-term performance through agricultural research, field trials, and stable global manufacturing supply chains.

| No. | Type | Common Shade Rate | Fabric Weight (GSM) | Typical Applications | Expected Lifespan |

|---|---|---|---|---|---|

| 1 | Knitted Shade Cloth | 30–90% | 90–200 | Greenhouses, vegetables, flowers, orchards | 3–8 years |

| 2 | Tape Woven Shade Net | 50–95% | 150–220 | Field crops, livestock areas, and large-scale shading | 3–8 years |

| 3 | Monofilament Shade Net | 40–80% | 120–180 | Organic farms, insect control systems | 3–10 years |

| 4 | Aluminet / Reflective Shade Cloth | 40–80% | 120–200 | High-temperature regions, greenhouse cooling | 5–10 years |

| 5 | Colored Shade Net | 40–70% | 150–220 | Blueberries, strawberries, tea, and ornamental flowers | 3–8 years |

| 6 | 100% Blackout Fabric | 99–100% | 280–400 | Cannabis, mushrooms, seedling rooms | 3–10 years |

| 7 | Insect Shade Net | 30–70% + 50 mesh | 130–180 | Organic vegetables, eco-friendly farms | 3–8 years |

| 8 | Premium Shade Sail | 90–98% | 340–420 | Patios, swimming pools, cafés, residential areas | 5–10 years |

| 9 | Waterproof Shade Sail | 95–100% | 420–550 | Carports, outdoor restaurants, canopy structures | 5–10 years |

| 10 | Flame-Retardant Net | 70–95% | 200–350 | Schools, exhibitions, public facilities | 5–10 years |

| 11 | Biodegradable Shade Net | 50–80% | 160–220 | Sustainable farms, organic projects | 2–5 years (biodegradable) |

| 12 | Scaffold Net | 70–90% | 200–300 | Construction sites, dust, and fall protection | 3–8 years |

Please note that actual performance will vary based on fabric weight (GSM), shade rate, and material composition. The following data should be considered general reference values, not absolute standards.

In-Depth Guide to Shade Cloth Types

After reviewing the quick reference table above, you should now have a general understanding of the global categories of shade cloth — and likely a sense of which type best fits your needs. To help you better understand the strengths and applications of each, let’s examine all 12 major types one by one.

1. Knitted Shade Cloth

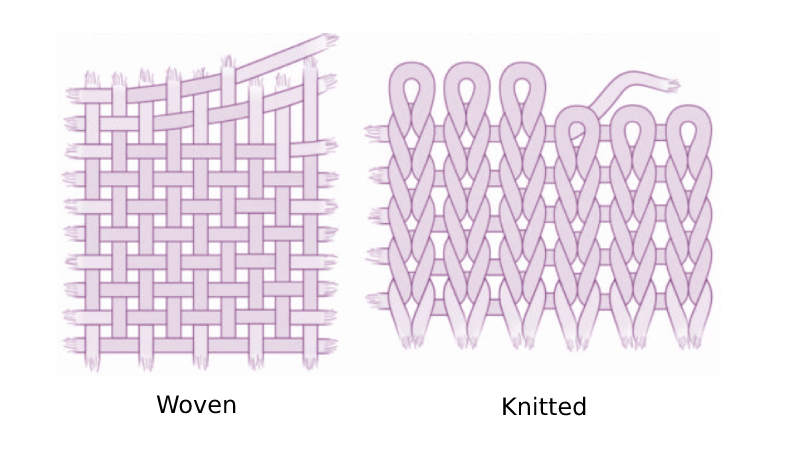

If your project involves greenhouses, orchards, or high-light vegetable production, knitted shade cloth is widely regarded as the global standard. It is manufactured from high-density polyethylene (HDPE) monofilament yarns woven through a knitted construction, producing a soft, flexible, and tear-resistant fabric. Compared with traditional woven shade nets, the knitted structure offers higher elasticity and better stress recovery — meaning it resists deformation and tearing under wind load, while remaining easy to cut and install.

Woven vs Knitted Shade Nets for Agricultural

According to long-term field studies by Utah State University (USU, 2014–2023), knitted shade cloth with a 50–70% shade rate can reduce sunburn in lettuce and peppers by 50–70%, while maintaining — and in some cases improving — photosynthetic efficiency. This balance between heat reduction and light diffusion enables crops to thrive under high solar radiation, resulting in better fruit quality and greater yield stability.

Don’t Miss: Agricultural Shad Cloth Types: Woven vs. Knitted

The key advantage of knitted shade cloth lies in its balance: it effectively reduces canopy temperature without significantly blocking the light plants need for healthy growth. This makes it ideal for vegetable greenhouses (tomatoes, lettuce, peppers), flower nurseries, and orchards located in mid- to low-latitude regions.

Key Features:

- Soft, flexible, and easy to install

- Excellent ventilation and tear resistance

- Not recommended for long-term use in high-wind areas; should be reinforced with structural support

2. Woven Shade Net

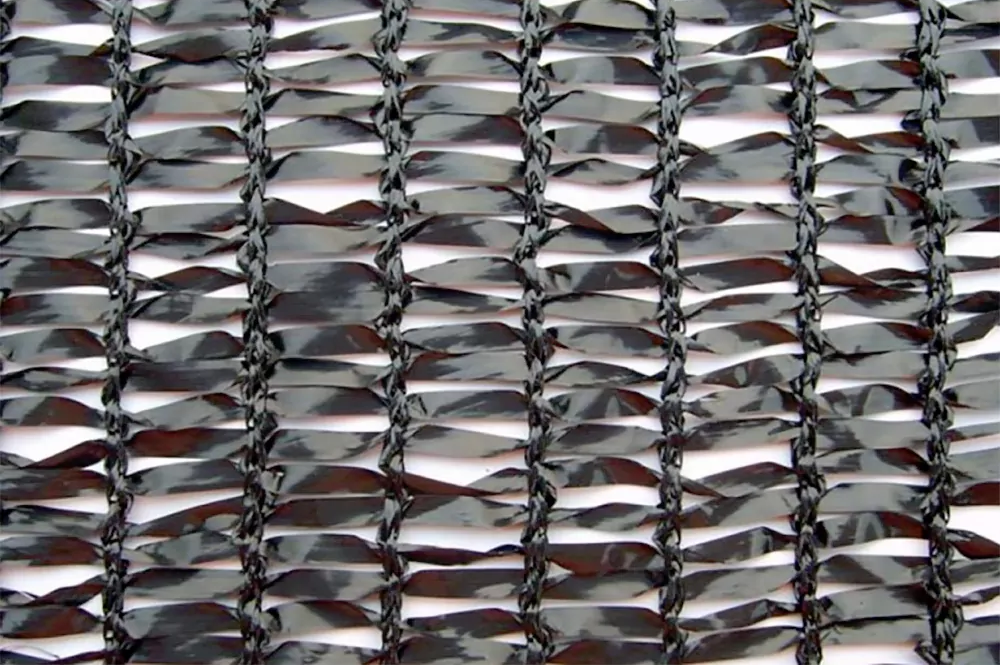

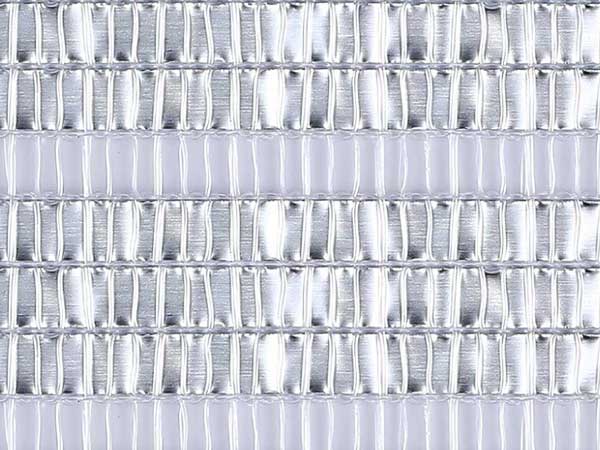

When your project covers a large area, has budget constraints, or requires high tensile strength, a tape-woven shade net is typically the most cost-effective solution. This fabric is made by interlacing flat polyethylene tapes, forming a tightly woven structure with uniform shading and excellent mechanical durability. It’s particularly well-suited for large-scale agricultural fields, livestock shelters, and extensive shading projects.

woven shade nets for agricultural

Field trials conducted by Washington State University (WSU) in apple orchards found that an 80% shade rate woven net reduced apple sunburn from 31% to just 7%, while also minimizing hail- and wind-related mechanical damage. Beyond shading, the woven structure provides effective wind reduction, dust protection, and partial pest exclusion, making it a practical choice for open-field farming.

However, the dense weave of tape shade nets limits air circulation, potentially leading to heat accumulation in humid climates. For this reason, they perform best in dry or windy regions, where ventilation is naturally enhanced.

Key Features:

- Cost-effective and structurally strong

- Even shade distribution with high tensile strength

- Limited ventilation; not ideal for humid climates

- Requires periodic cleaning to maintain shading efficiency

INSONSHADE Recommendation:

For arid or high-wind environments, use 70–80% shade. If installed in humid climates, incorporate ventilation gaps or consider knitted alternatives for better airflow.

3. Monofilament Shade Net

If your project requires both shading and pest control, a monofilament shade net offers an excellent balance. It is woven from round-section HDPE monofilament fibers, forming a highly uniform mesh structure. It can be used alone or combined with insect mesh to create an integrated “2-in-1 shading and insect barrier system.”

Monofilament Black Shade Net by INSONSHADE

Monofilament shade nets are ideal for organic farming, disease-sensitive crops (such as strawberries and leafy greens), and eco-farming projects where reduced pesticide use is a priority. They provide a balanced combination of sun protection, insect exclusion, and wind mitigation, supporting sustainable and chemical-free agriculture.

Key Features:

- Uniform light distribution and ventilation

- Excellent insect resistance; suitable for organic cultivation

- Slightly higher cost than knitted nets

- Over 70% shading may reduce photosynthesis efficiency

INSONSHADE Recommendation:

If pest exclusion is your primary goal, choose 40–50% shade with 50 mesh. If temperature reduction is more critical, increase shading to 60–70%. Always select materials with UV stabilizers to prevent fiber brittleness after three years of exposure.

4. Aluminet / Reflective Shade Cloth

For projects in extremely hot or high-radiation regions — such as the Middle East, Southern Europe, Northern Australia, or the Mexican plateau — the aluminized reflective shade cloth is unmatched in performance. Instead of simply blocking sunlight, it reflects a portion of solar radiation away from the surface, dramatically reducing heat load inside greenhouses while maintaining sufficient light intensity.

Aluminet Reflective Shade Fabric for Commercial Greenhouse

Greenhouses using 75% reflective aluminet experienced an additional 5–8°C (9–14°F) reduction in temperature compared to conventional black shade cloth, while visible light decreased by only 25%. This balance enables crops to receive adequate photosynthetically active radiation (PAR) without the risk of heat stress, flower drop, or fruit burn.

Related Reading: Best Greenhouse Material for Hot Climate

The strength of aluminet lies in reflection, not obstruction. By reflecting infrared radiation, it lowers leaf and canopy temperature and improves light uniformity throughout the greenhouse. It’s particularly recommended for tomatoes, roses, blueberries, and other temperature- and light-sensitive crops.

Key Features:

- Superior cooling efficiency and thermal control

- Reflective surface improves light distribution and crop quality

- Higher cost than standard black nets

- Requires proper installation and regular cleaning to maintain reflectivity

INSONSHADE Recommendation:

For greenhouse agriculture in high-heat regions, select 60–75% shade aluminet. For commercial or architectural applications (parking areas, canopies, or pergolas), consider double-layer reflective structures for better wind stability. Clean regularly to remove dust or salt buildup that can reduce reflective performance.

5. Colored Shade Net

For high-value crops such as blueberries, strawberries, tea, or ornamental flowers, the color of light plays a critical role in plant development. Colored shade nets are designed using light-spectrum modulation technology — they don’t just reduce sunlight intensity but also alter wavelength composition to influence plant physiology.

Different-colored shade nets have an impact on crops

Research from Frontiers in Plant Science, the USDA, and several European universities shows that different colors of shade cloth can significantly affect yield and quality. Red nets can advance strawberry harvests by 7–12 days; blue nets increase blueberry sugar content by around 8%; and pearl-white nets enhance amino acid levels in tea leaves, improving flavor and aroma. Unlike dyed fabrics, these nets use optical additives or metallic oxides to modify light transmission. In regions with strong sunlight, they also help prevent leaf burn and stimulate growth hormone production, making them increasingly popular in premium horticulture and organic farming.

Key Features:

- Adjusts light spectrum to improve fruit color and sweetness

- Ideal for high-value crops and precision agriculture

- More expensive than standard black nets

- Performance depends on local light conditions and crop sensitivity

INSONSHADE Recommendation:

Use 40–60% shade for orchards; up to 70% for light-sensitive crops like tea. A red + pearl net combination works well for blueberries and strawberries, improving fruit appearance and market value

6. 100% Blackout Fabric

In applications that require total light exclusion, such as light-sensitive cultivation or photoperiod control, standard shade cloth is insufficient. Blackout fabric — also called light deprivation cloth — is used in cannabis, mushroom, ginseng, and nursery production, where precise light cycles are essential.

Blackout shade curtain used for light-dep greenhouse – Flame-Retardant

Constructed from multilayer polyester and black composite films, these fabrics are both opaque and water-resistant. When paired with motorized systems, they enable precise light scheduling for greenhouses and controlled environments. They are also used in research and specialty mushroom facilities.

Key Features:

- Near-total light blockage (up to 99.9%)

- Suitable for photoperiod-sensitive crops and light-deprivation systems

- Durable, reusable, and partially water-resistant

- Higher cost and requires professional installation

INSONSHADE Recommendation:

Use a three-layer structure: UV-resistant outer layer + black core + reflective inner layer. Maintain ≥99% shading for cannabis and ginseng. Combine with automatic curtain systems for optimal control and longevity.

7. Insect Shade Net

When your project needs both shading and pest control, insect shade nets are the most efficient choice. These composite fabrics merge shading and insect protection in a single layer, balancing light reduction, airflow, and pest exclusion. In certified organic farming systems in the EU and North America, they have become a standard solution. A 50-mesh net with 30–60% shading effectively blocks thrips, whiteflies, and aphids while maintaining ventilation — reducing pesticide use and meeting sustainability goals.

Red insect shade netting polytunnel

INSONSHADE’s field data from Southeast Asia and Southern Europe show that insect shade nets lower pest-related damage by more than 50% while improving humidity control inside greenhouses. Over time, they offer greater economic efficiency than separate shading and insect nets, particularly for export-oriented organic farms.

Key Features:

- Combines shading and insect protection

- Reduces pesticide dependency

- Excellent ventilation, suitable for moderate shading needs

- Slightly higher cost than knitted shade cloth

INSONSHADE Recommendation:

Choose 40–60% shade and 50–60 mesh for most crops. For hot climates, use a silver-gray reflective outer layer to reduce temperature and enhance pest deterrence.

8. Premium Outdoor Shade Fabric

For residential, commercial, or architectural projects, shade is not just functional — it’s part of the design. Premium shade sails provide both performance and aesthetics. Made from dense knitted fabric (340–420 g/m²), they offer strong UV protection and tensile stability. Regulations in Australia, New Zealand, and some U.S. states require public outdoor areas to use fabrics with at least 95% UV blockage. Tests show they can reduce surface temperatures beneath them by 8–11°C in peak summer conditions.

Shade cloth for playground

Unlike agricultural nets, premium shade sails focus on structural tension and appearance. Typically shaped as triangles or rectangles, they use stainless-steel fittings and tensioned cables for stability. Common applications include cafés, swimming pools, patios, and private gardens.

Key Features:

- Strong, visually appealing, and UV-resistant

- Suitable for commercial and residential use

- Excellent wind resistance; requires hardware inspection

- Recommended replacement every 5 years in full-exposure environments

INSONSHADE Recommendation:

In coastal or high-wind regions, use reinforced designs (≥400 g/m², double-stitched edges). For rain protection, consider the waterproof shade sail described in the next section.

9. Waterproof Outdoor Shade Fabric

In tropical or monsoon regions, waterproof performance is just as important as shading. Waterproof shade fabric is an upgraded version of traditional models, featuring a PU or PVC coating on a high-density polyester or HDPE base fabric. This design not only blocks sunlight but also provides effective protection against sudden rainfall, making it ideal for all-weather commercial spaces such as outdoor restaurants, cafés, and carports.

Waterproof Shade Cloth by INSONSHADE

Compared to regular shade sails, waterproof versions are heavier (typically 420–550 g/m²) and use high-frequency welding or waterproof seam taping to prevent leakage. However, limited breathability can lead to heat buildup if the installation angle is too flat. To ensure proper water drainage, a slope of at least 20° is recommended during installation.

Key Features:

- Provides both sun and rain protection

- Ideal for commercial and public areas

- Lower breathability; requires a proper slope for ventilation and drainage

- Higher cost but greater weather resistance and longevity

INSONSHADE Recommendation:

In humid or rainy environments, use dual-sided PVC-coated fabric. For carports and outdoor dining areas, use stainless-steel tension cables and adjustable fittings to improve durability and aesthetics.

10. Flame-Retardant Net

In schools, exhibitions, and sports facilities, safety standards take priority over shading performance. Flame-retardant shade nets are specifically engineered for such environments. They are manufactured by either blending fire-retardant compounds into the base material or by applying a flame-resistant coating, allowing the fabric to self-extinguish upon exposure to an open flame.

Flame-Retardant Shade Cloth

If you are using them in the USA, these products must pass U.S. standards such as CPAI-84 and NFPA-701, which regulate the fire safety of outdoor textiles. For example, in California and Texas, outdoor shading structures are required to provide fire certification documents.

Despite their safety focus, these nets maintain good shading and weather resistance, making them suitable for:

- School playgrounds and spectator stands

- Temporary exhibitions and event tents

- Airports, stadiums, and public spaces

Key Features:

- Complies with CPAI-84 / NFPA-701 fire safety standards

- High flame resistance; suitable for public facilities

- Slightly heavier and more expensive than standard shade nets

- Customizable in color and light transmission for aesthetic integration

INSONSHADE Recommendation:

For long-term installations, use fiber-blended flame-retardant fabrics instead of surface-coated versions to prevent degradation from UV and rain exposure. Perform regular fire-resistance testing to ensure sustained safety compliance.

11. Scaffold Net

Construction safety nets have unique performance requirements beyond shading — including fall protection, dust control, and impact resistance. Scaffold nets are essential components of occupational safety standards worldwide. Beyond construction, scaffold nets are also used in municipal works, road barriers, and temporary site enclosures. They are typically produced in high-visibility green or orange to enhance on-site safety awareness.

Scaffolding Enclosure

Key Features:

- Strong, impact-resistant HDPE woven structure

- Provides shading, dust protection, and fall prevention

- Meets OSHA safety and performance requirements

- High-visibility color options for enhanced site safety

INSONSHADE Recommendation:

For coastal or high-rise projects, choose flame-retardant and UV-stabilized HDPE for added protection. On long-term construction projects, conduct strength testing every six months to ensure ongoing compliance and worker safety.

12. Biodegradable Shade Net

While not yet widely adopted, biodegradable shade nets are quickly emerging as a significant trend in sustainable agriculture and eco-friendly construction. These next-generation materials are designed for farms and projects seeking to minimize plastic waste and environmental impact.

Lightweight burlap shade cloth for vegetables by stowaway43

Most modern biodegradable shade nets are made from bio-based polymers such as PLA (polylactic acid) or PBAT, which naturally decompose within 2–5 years, leaving no chemical residues. In addition, some traditional natural fibers — such as jute and coir (coconut husk fiber) — are being revisited as renewable alternatives. These natural-fiber nets contain no synthetic additives and can safely return to the soil after use, making them ideal for organic and short-cycle agricultural systems.

Key Features:

- Made from renewable, plant-based materials

- Fully biodegradable within 2–5 years

- Complies with EU REACH and USDA BioPreferred standards

- Shorter lifespan and higher cost than HDPE fabrics

INSONSHADE Recommendation:

Best suited for organic farms, government sustainability projects, and short-term greenhouse installations (≤5 years). For tropical regions, we recommend UV-stabilized or blended PLA formulations to extend durability. INSONSHADE is also testing hybrid designs that combine natural fibers with biodegradable polymers to improve strength while maintaining full degradability.

Conclusion

Shade cloth is no longer just a passive tool for blocking sunlight — it has become one of the most efficient and sustainable climate-control solutions across agriculture, construction, and public spaces. From knitted and woven nets to aluminized, reflective, and color-spectrum fabrics, each type is built on specific scientific principles and tailored to unique environmental conditions. Choosing the right material can reduce energy and irrigation needs, improve crop quality, extend the lifespan of structures, and enhance overall human comfort.

If you’re sourcing shade cloth for agriculture, greenhouses, or outdoor architectural projects, INSONSHADE is here to help. With over 20 years of manufacturing expertise and customers in more than 30 countries, we provide data-driven recommendations and high-quality materials designed for performance and durability.

(And if you spot any inaccuracies in this guide, we’d genuinely appreciate your feedback — thank you for reading.)

References

- Utah State University Extension. Using Shade for Fruit and Vegetable Production.

- Washington State University Tree Fruit Research & Extension Center. The Influence of Protective Netting on Tree Physiology and Fruit Quality of Apple — A Review.

- MDPI — Agriculture Journal. “Shade Nets in Modern Horticulture: Effects on Crop Quality and Microclimate.”

- ScienceDirect. Effects of Shading Materials on Agricultural Microclimates and Crop Performance.